Innovations by MINDEF and SAF personnel led to man-hour savings of more than 500,000 hours, as well as contributed to a greener SAF.

Inspecting the interior fuel tank of the Republic of Singapore Air Force's (RSAF's) CH-47 Chinook helicopter used to be a laborious process.

Three personnel were required to don their safety equipment which included wearing PPE (Personal Protection Equipment). They then have to crawl into the fuel tank through a small opening and work in a confined space for up to eight hours.

Today, just one person is required to perform the inspection. The time taken to do so has also been reduced to just one hour – thanks to the SwiftEye.

This latest innovation by the 6 Air Engineering and Logistics Group (AELG) is a robotic inspection arm designed to enable Air Force Engineers (AFEs) to inspect the interior fuel tank of the helicopter without having to enter it.

A high-definition camera and LED light are fitted at the front of the arm to transmit video to a tablet so that the AFE can see what is going on in the fuel tank from the outside.

The arm is controlled by a 3D-printed controller frame which mimics what the former is doing. This allows the AFE to determine the location of the fault more accurately.

Using commercial, off-the-shelf products and 3D printing, the 5-person team took close to six months to come up with the prototype, said Military Expert (ME) 4 Cherlyn Koh, who took on this project as team lead in June 2021.

"This project involved the integration of software and hardware so we took a lot of time to refine the program, change the design of the hardware in order to achieve the requirements and (level of) control needed," explained the 26-year-old Officer In-Charge of 816 Squadron (SQN).

"Because the inspection (used to be) physically demanding and manpower intensive, I'm very proud that this has helped the AFEs to make their work more efficient, safer and easier."

The spirit to innovate

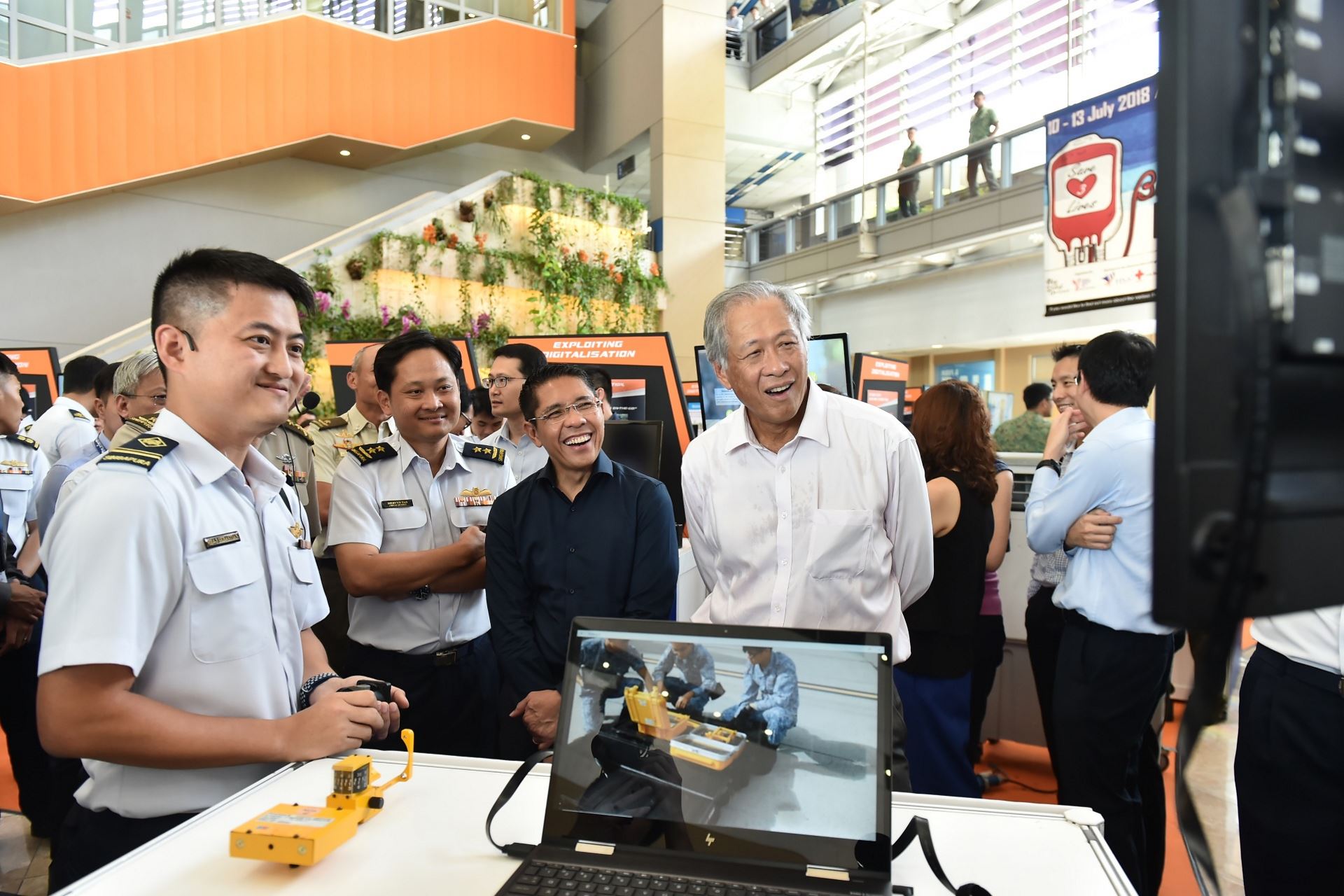

The SwiftEye was one of the projects which led 6 AELG to receive the Minister for Defence Award (MDA) at the IGNITE Innovation Symposium 2023 held at the Ministry of Defence (MINDEF) on 11 Jul.

Speaking at the awards presentation ceremony, Minister for Defence Dr Ng Eng Hen commended the award recipients and their spirit of innovation to drive MINDEF and the SAF forward in a rapidly changing environment.

"We will always need that innovative spirit of the men and women in our organisation to make sure that our platforms and systems function and are optimised against different scenarios," said Dr Ng.

He added that the attitude of never accepting things as they are, and overcoming obstacles that arise were crucial to improve day-to-day workings as well as win battles and wars.

"We have to keep this innovative spirit alive and this is the core purpose of IGNITE. It is not just good to have but completely necessary for mission success."

Smoother fighting operations

For 2nd Warrant Officer (2WO) Denesh S/O Mogan, 36, coming up with the 3D-printed torchlight mount for the SAR21 rifle was one of the highlights of his innovation process in March last year.

Without the mount, soldiers have to move their hands to switch on the torchlight and this would take them away from their firing posture for a few seconds during operations.

With the mount, they can now switch on the torchlight while remaining in a firing position.

As project lead, 2WO Denesh and his team of six took close to six months to come up with the design for the torchlight mount.

The team took their work seriously and trialled the mount with three battalions. After receiving feedback that the mount often got caught in the vines when bashing through jungles, the team tweaked the design and made the device shorter.

The torchlight mount is now being used by Guardsmen. Plans are also in place to finalise the prototype and implement it across the Army.

When asked how he felt about being recognised for his innovation, 2WO Denesh, who is currently the Company Sergeant Major of the Army Deployment Force, said: "While there's a sense of accomplishment, innovation is not easy.

"You can always start on an idea but there are obstacles that you need to overcome and you must know that you are not alone. There are a lot of avenues in the Singapore Armed Forces (SAF) that will help you out."

Going green with BSAT

During his stint as a gunnery officer on board the Republic of Singapore Navy's (RSN's) mine countermeasure vessel RSS Kallang in 2021, Captain (CPT) Ng Jing Xi saw how his fellow seamen prepared the "killer tomato" target out at sea for live-firing.

Four sailors were required to inflate the killer tomato and the time taken to do so was about 30 minutes. Preparing the target often became more difficult in rough sea states.

In addition, the PVC killer tomato contributed to plastic waste in the ocean after every live-firing.

As part of the RSN's sustainability efforts, CPT Ng explored options for an alternative shooting target.

The 28-year-old Staff Officer in Training Plans and System Branch from the Naval Training Department found a company who dealt with biodegradable materials and decided to work with them.

They eventually supplied CPT Ng with a prototype, which he adapted it to the requirements for live-firing.

Made from recycled raw materials comprising corrugated boards printed with water-based soluble ink and starch-based adhesives, the Biodegradable Small Arms Target (BSAT) is fully biodegradable.

As it is smaller (1.5m in height as compared to the 3m-tall killer tomato) and lighter, it now takes two men to deploy the BSAT in just five minutes. Its size also makes it a realistic target for sailors to hone their gunnery competency.

Following a successful 6-month trial across the different RSN platforms last March, the BSAT has since been implemented for all small arms firing, including handheld weapons and system guns up to 25mm calibre.

Daring to do

CPT Ng is currently working on a bigger target so that it can be used with the 76mm OTO Melara gun. His idea is to combine four BSATs together using a modular attachment.

For his innovation and efforts, he received the MINDEF Dare-to-Do award.

"I am honoured to be recognised for the efforts that I put in for the BSAT, knowing that this was a first-of-a-kind target. We were quite happy that people were very supportive of the idea… and when it comes to innovation, people are accepting and encouraging," said CPT Ng, who was the project lead for the two-man BSAT team.

"We also had support from our formation commanders, and we managed to get participation across the entire RSN rather than just within our formation."