SIMPLE IDEAS, BIG SAVINGS

The Ministry of Defence Economy Drive movement aims to inculcate financially prudent habits in the organisation. PIONEER takes a look at two projects that brought about more than $1 million in savings in the past year.// STORY BENITA TEO

// PHOTOS TAN YONG QUAN & KENNETH LIN

Less is more

What’s the problem?

The SAF Ammunition Command (SAFAC) was purchasing new 120mm Armour Piercing Fin Stabilised Discarding Sabot (APFSDS) ammunition from Germany for the Leopard 2SG tanks.

But the pallets (external structures holding together the ammo containers) used for storage and shipment did not optimise storage space. The metal bars that reinforced the pallet, for instance, took up space that could be used to fit two more containers of ammo.

In addition, the pallets were 1.2m by 1m by 1.1m, leading to wasted space when packed in a 20-foot shipping container. This meant higher costs when shipping the ammo.

That's the solution!

SAFAC and the Defence Science and Technology Agency (DSTA) approached the original equipment manufacturer (OEM) with a new pallet system for the APFSDS ammo.

Over two years, they worked together to come up with a design that would fit the SAF's needs while reducing production costs. "The OEM was initially reluctant to invest in the research and development," said DSTA Project Manager (Systems Management) Terence Tan, 35.

The original pallet met the needs of the German Army, which the OEM was producing for. The team therefore took a cost-savings approach with the OEM.

We made this!

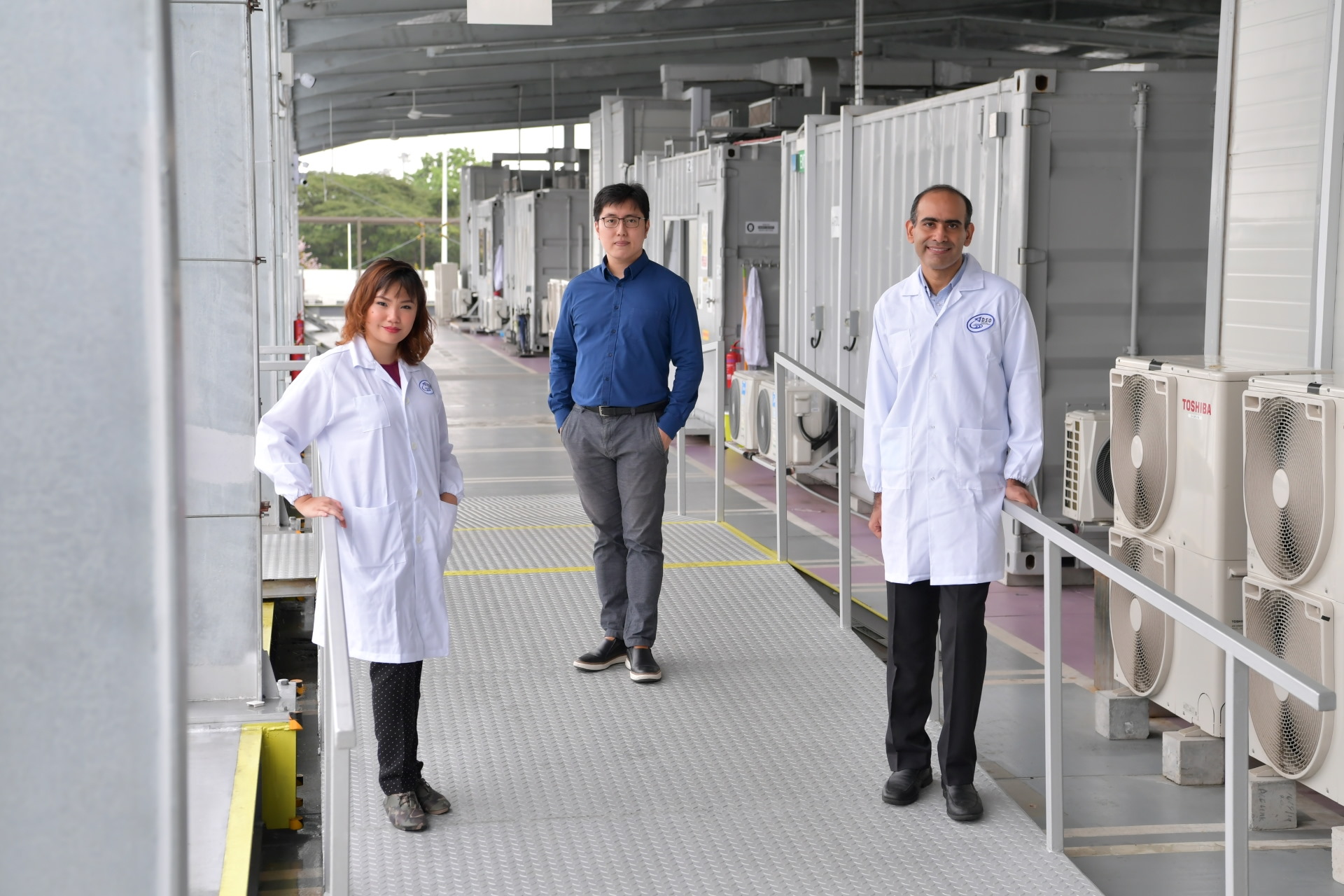

The new design replaced the solely-metal structure with military-grade wooden pallets held together by wood and metal adaptors. It also did away with the heavy metal reinforcements.

The end product was smaller and cheaper to produce, but could hold more ammo — up from 14 to 16 per pallet.

They could also pack 20 (instead of 16) of these new pallets into a shipping container, thus saving on shipment costs during delivery and when the ammo is transported for overseas exercises.

It also helped to maximise space in the SAFAC ammo depot. Ms Eilenia Tay, a senior manager in Headquarters SAFAC, elaborated: "With the new design, there are more rounds per pallet, so we can fit more rounds into the same amount of space."

The 36-year-old added: "We've shown the end users (the men who unload the ammo) the design and they are pleased as the rounds can still be easily retrieved."

How much did we save?

$640,000!

Venting a problem

What's the problem?

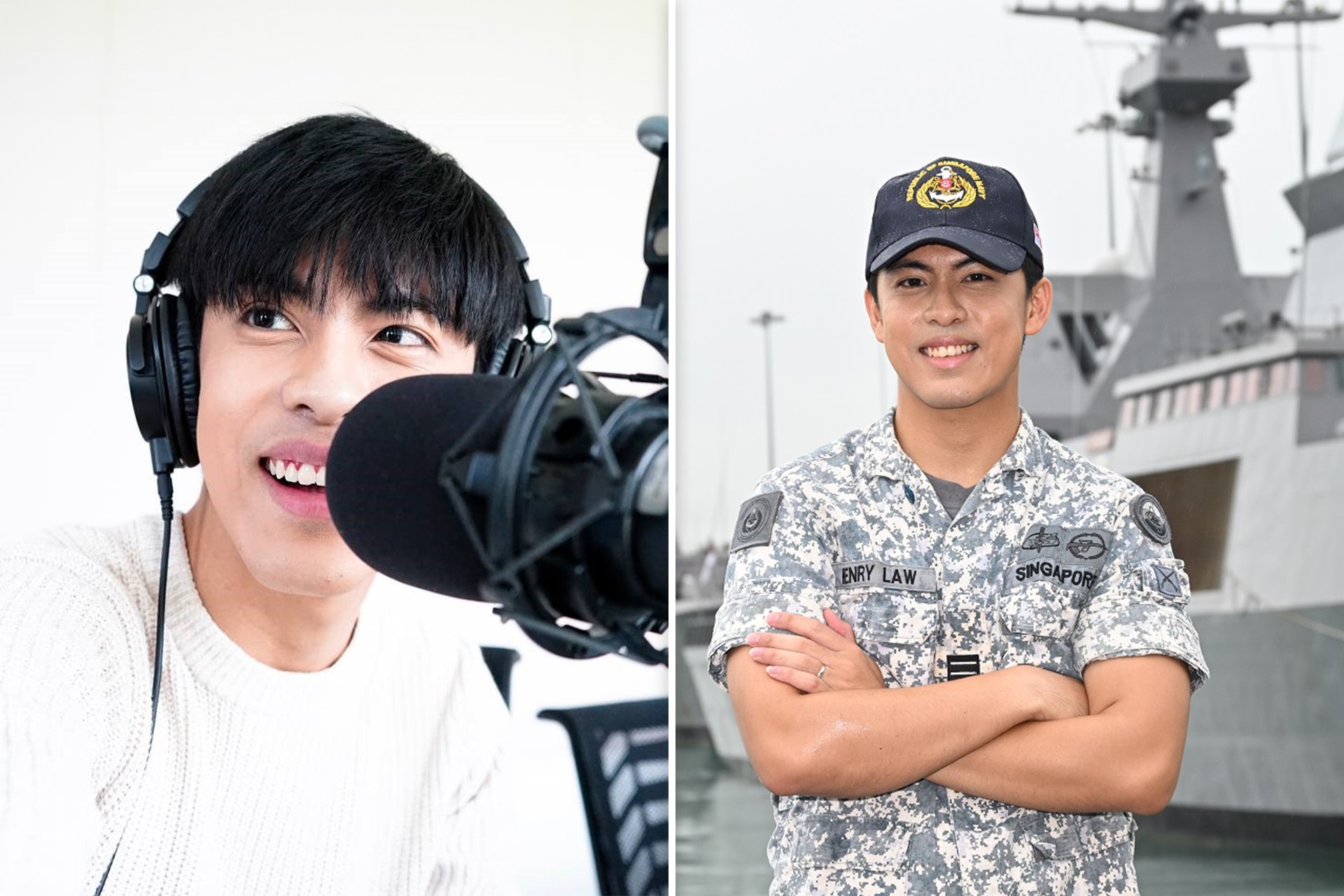

Overheating was causing the Ship Management System computers on the Republic of Singapore Navy's Formidable-class frigates to fail.

There was poor airflow inside the fully-enclosed metal cabinets that the computers were kept in, causing the Central Processing Units to hit temperatures of up to 66 degrees Celsius. In 2014 alone, 86 incidents such as lagging response were reported.

That's the solution!

A team from Naval Logistics Command, Naval Logistics Department (NLD) and 185 Squadron (SQN) worked with ST Engineering (Electronics) to find a way to fix the problem.

Instead of replacing the cabinets with bigger ones, they discovered that they could modify the existing ones and redesign their doors to improve the airflow inside.

NLD Lead Engineer (Electrical Systems Branch) Military Expert (ME) 4 Aden Phua, 26, explained: "Besides enhancing the airflow, this costs significantly less than replacing the entire cabinet. There is also less operational downtime for the implementation."

We made this!

The team came up with various modifications for the computer cabinets. These included installing fans inside the cabinets for air to flow in and out efficiently, and placing vents and metal honeycomb filters on the doors. A total of nine configurations were designed for the frigate's 42 cabinets which carry 45 computers.

These new configurations have allowed temperatures inside the cabinets to stay at an optimal 25 degrees Celsius, and successfully eliminated overheating and poor performance in the computers.

Even while running 24/7, the computers no longer encounter downtime from problems of overheating.

As an added bonus, the maintenance of the computers and cabinets is also much easier.

"Cleaning of the cabinets used to be carried out every two years, and could only be done at the shipyard," said ME4 Manicka, a Squadron Electrical and Control Systems (ECS) Engineer in 185 SQN. The 54-year-old was RSS Steadfast's pioneer Chief ECS.

"Now, ECS operators just have to unscrew the nuts to remove the filters and clean them with a brush. This is done on the ship about once a month to ensure unobstructed airflow."

How much did we save?

$970,000!