Web Content Viewer

Web Content Viewer

“Obsolescence is a prevailing issue. Traditionally, the approach is to buy new products to replace obsolete parts but that usually takes time and is costly.” To improve Our Army’s local repair capabilities and cost savings, the Maintenance and Engineering Support (MES) Formation, with joint efforts from Defence Partners, started Project Remanufacturing (REMAN), pooling engineering resources to combat obsolescence in our platforms and equipment.

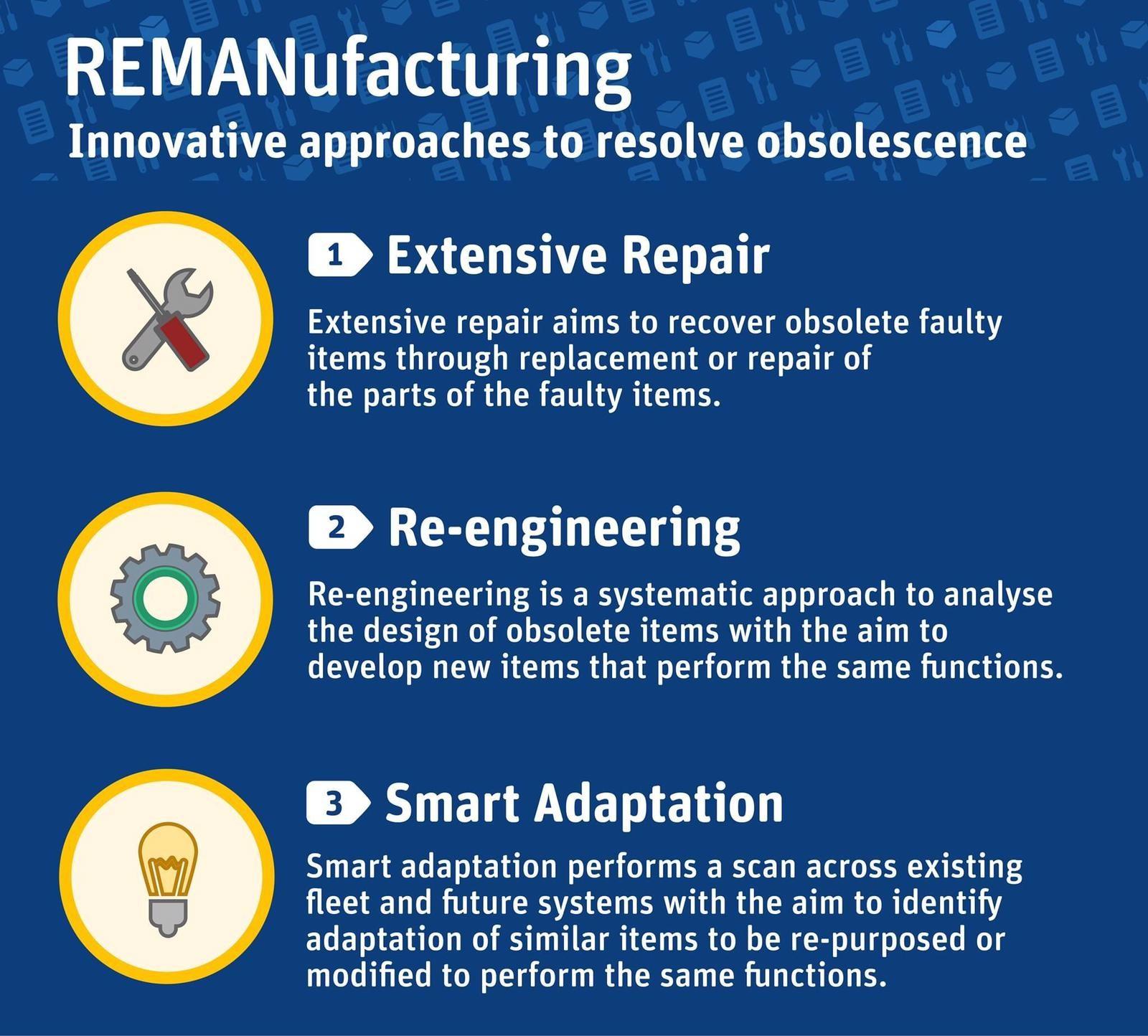

To gain sufficient first-hand experience on how best to optimise repair and remanufacturing efforts, Project REMAN started small and gradually began to expand their capabilities to focus on larger projects. Consisting of three initiatives - Extensive Repair, Smart Adaption and Re-Engineering, the project has made great strides in their progress, accumulating millions in cost savings.

Infographic contributed by HQ MES

To learn more about the project, we spoke to some of the team members, ME4 Desmond Ang, ME3 Soh Boon Seng and ME3 Ramesih, to understand more about their journey so far and the challenges they faced.

How do you feel, being part of the team that is helping develop new methods to combat obsolescence in the Army?

ME4 Desmond Ang: Project REMAN has benefited me personally as it has broadened my horizons, changing my perspectives on the way we deal with obsolescence. I have learnt to constantly challenge the status quo, and look for ways to improve things. The learning experience that I have gained from this project will certainly help in reducing the downstream issue of obsolescence in future when I handle new equipment purchases.

ME3 Soh: I feel honoured to be able to help our organisation solve the prevailing obsolescence issue and have personally learnt how obsolescence management could be applied for our other aging equipment.

ME3 Ramesih: When we first began this project to combat obsolescence, we were faced with a steep learning curve. I am extremely happy and proud that we had a breakthrough and were able to develop feasible solutions to combat obsolescence. Being a part of this project and gaining this knowledge will definitely be of great use in the future.

ME5 Chia Kian Chye, Head Unmanned Systems and Robotics Branch, HQ MES

ME4 Desmond Ang, Lead Engineer (Bronco All Terrain Tracked Carrier), HQ MES

ME3 Ramesih, Engineer (Singapore Self-Propelled Howitzer Primus), HQ MES

ME3 Soh Boon Seng, Engineer (Bronco All Terrain Tracked Carrier), HQ MES

What were some of the challenges you and your team faced?

ME4 Desmond Ang: One of the challenges is to be able to correctly identify older hardware and replacing them with compatible replacements. This had to be solved through extensive trial and error.

ME3 Soh: We had to ensure that the system used was compatible with the platform we were repairing. This includes having to deepen our understanding and knowledge of the system, before being able to identify compatible solutions for replacement of the obsolete hardware.

ME3 Ramesih: The challenges we faced were mainly focused on ensuring that components remain reliable. We also built our local capabilities to prevent obsolescence by working with our project partner to make sure that components used are readily available in the respective industries.

What are your expectations for the project in the future?

ME3 Soh: Though increasingly challenging, especially with the current COVID-19 situation affecting product delivery timeline, this project definitely has much potential in helping Our Army maintain its capabilities at a sustainable cost.

ME3 Ramesih: This project explores the different possibilities to combat obsolescence. With the speed that technology is advancing, it is essential that our team adapt accordingly, continuing our goal of combatting obsolescence in the Army.

This endeavour is a great development for Our Army in dealing with the prevailing issue of obsolescence. With the skills and insights that the team has gained through Project REMAN, we are confident that Our Army will be better equipped to deal with obsolescence, thereby leading to longer lasting platforms and equipment.

Written by: LCP Steve Lee (Army News)

Photography by: CPL Isaac Benjamin Ong (Army News)